CASE STUDIES

Vision Guided Positioning for Robotic Screw Driving

In order to increase efficiency and flexibility, an automotive HVAC company switched from using conveyors to using AGVs on their assembly lines. Although this achieved their goals, it has also introduced a few problems. Foremost, the exact location of the fixture was no longer guaranteed. This would cause a major problem with normal robotic screw driving.

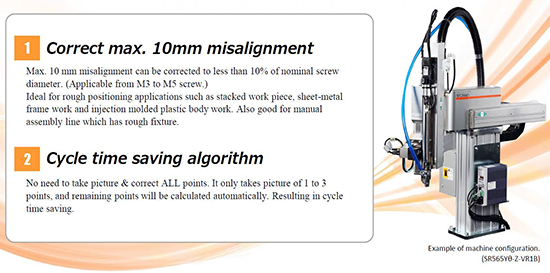

We evaluated the application and integrated our Vision Guided Position SR565 robot. This turn-key package utilizes an advanced vision system to locate the screw bosses and adjust the robots taught points. It also includes everything needed to feed and drive the screw. A single HVAC unit needs 17 screws driven. Each screw position is taught separately, then the cameras are trained to locate each screw boss. The vision system can be used in two different modes – a single picture for each location, or it can take three pictures and skew the locations based on that data. This unique application required using both types of programming on a single part.

After setup, the AGVs only need to locate the fixture within 10mm of the original taught point and the Vision Guided SR565 robot is able to drive screws into all locations.