CASE STUDIES

Complete Data Driven Screw Driving

Detroit Thermal Products, an automotive HVAC supplier, needed to update their screw driving processes to not only automate these functions, but capture the data for analysis. For each screw driven into their parts, they needed to capture the torque, angle, stroke and screw height data. Additionally, because of workflow requirements, two separate screw driving systems were needed in each workcell.

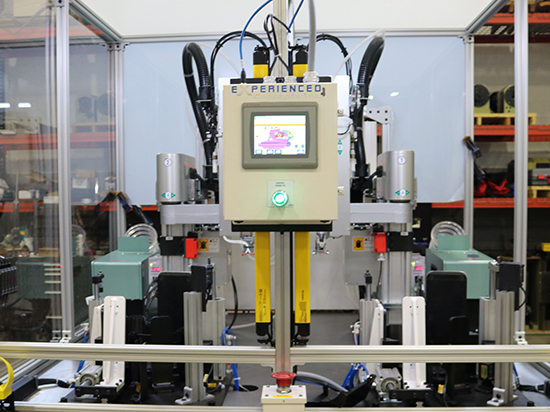

Working with their builder, Experienced Concepts Inc., we developed a solution to fit all their needs. Using our SR565 robots with servo Z-axis control and vacuum spindles, ECI was able to integrate the two robots into a packaged workcell that minimized footprint. We collected the torque and angle data from our NX motors, as well as the stroke data from the Z-axis servo and the screw height data from an LVDT, in our RC5500 robot controllers. Control of the workcell was by an Allen Bradley PLC and we used Ethernet between the PLC and the two robot controllers for all control and data transfer. All data is accessible through the workcell’s HMI. While the raw data is important for logging and analysis, ECI also graphically represented the data, making it useful to the operating and maintenance staff.

Fulfilling both their functional and data collection requirements, these workcells will allow Detroit Thermal Products much more control over the screw driving processes and be assured they are assembling quality parts each and every cycle.