CASE STUDIES

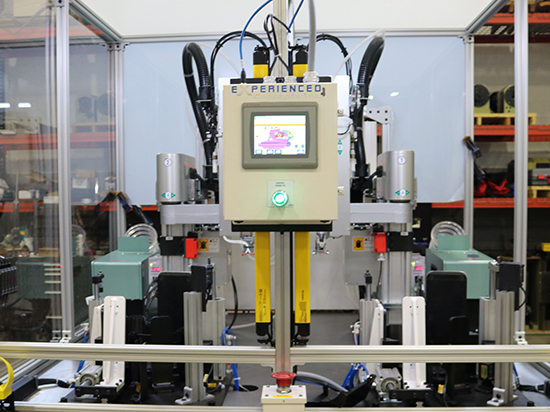

Complete Data Driven Screw Driving

An automotive HVAC supplier needed to capture the torque, angle, stroke and screw height data for each screw driven into their parts. Our solution enabled torque and angle data to be collected from our NX motors, as well as the stroke data from the Z-axis servo and the screw height data from an LVDT, in our RC5500 robot controllers.

Read More

Servo Controlled Single Spindle for Thrust Control

An automotive glass company was having difficulty assembling a rear-view mirror. The equipment they were using was a single-spindle screw driver with a pneumatic cylinder z-axis and a bowl feeder. We evaluated the application and proposed our FM513V-Z single spindle driver. A turn-key package with everything needed to feed and drive the screw, the FM513V-Z uniquely addressed each of their problems.

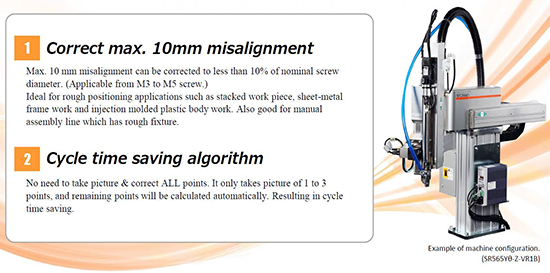

Read MoreVision Guided Positioning for Robotic Screw Driving

In order to increase efficiency and flexibility, an automotive HVAC company switched from using conveyors to using AGVs on their assembly lines. Although this achieved their goals, it has also introduced a few problems. Foremost, the exact location of the fixture was no longer guaranteed. This would cause a major problem with normal robotic screw driving. We evaluated the application and integrated our Vision Guided Position SR565 robot.

Read More