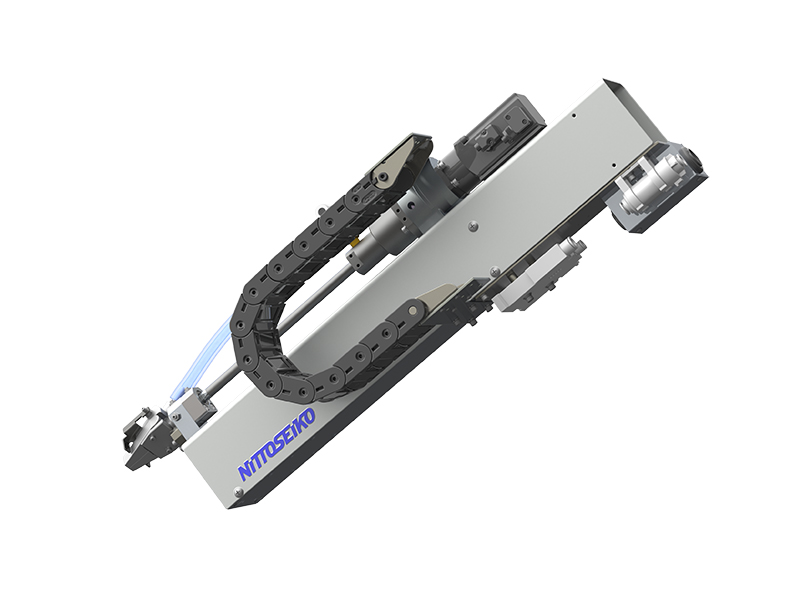

FM513VZR

This product is a single-axis automatic screw driving machine that is compatible with small-diameter screws in the M2 to M5 class. By minimizing the thrust force during screw driving, it contributes to reducing the load on the workpiece and reducing screw driving defects such as seizing. In addition, it has achieved cycle time reduction by improving thrust force control.

By offsetting the weight of the screwdriver bit lift mechanism against the pressing force (self-weight cancellation function), the thrust force during screw tightening is reduced by approximately 70% compared to conventional models, making it possible to tighten screws gently on the workpiece. This prevents seizing and diagonal tightening due to excessive thrust force. In addition, by reducing the thrust force when detecting screw height fault, the deflection of the workpiece is reduced, and the accuracy of the detection is improved. Furthermore, in situations where high thrust is required, such as when tightening screws for the final time, or depending on the characteristics of the workpiece and the tightening torque, it is also possible to tighten screws with the same thrust as conventional machines.

The thrust can be set in actual pressing force N (Newton), rather than the conventional percentage, making it possible to perform teaching work in a more intuitive way.